Dry Ice Blasting Smoke and Soot Removal

Dry Ice Blasting: The Process, Techniques, Benefits and Use in Restoration

Dry ice blasting has gained popularity in the Restoration business for restoring homes and buildings affected by fire damage. Dry ice blasting uses carbon dioxide in its solid form accelerated and pressurized air steam at a surface to clean it. It is ideal for restoring wood, concrete, brick, and building materials because of its efficiency and effectiveness in removing smoke odor, char, soot, mold, and mildew from these surfaces. In addition, cleaning with dry ice is a non-abrasive solution, and it eliminates manual cleaning, harmful chemicals, and water, which is why the insurance industry and adjusters are now recommending the use of dry ice more and more.

There is a great deal to understand and learn regarding using dry ice in Restoration.

The Process

The dry ice process, simplified into one sentence: “When fine CO2 (dry ice) particles are “blasted” onto a surface, the unwanted contaminants freeze and fracture, then an explosion of energy takes place, resulting in the thorough removal of the unwanted coating, such as grease, paint, and rust.”

- Stage One: The first thermal shock stage of the dry ice blasting process results in the rapid freezing of the surface contaminants, causing them to become brittle and fractured.

- Stage Two: The dry ice pellets are accelerated, blasting the cleaning surface and breaking up the brittle and fractured coating or contaminant.

- Stage Three: An explosive event is caused by the instant expansion of gas due to dry ice’s rapid heat transfer and sublimation (vaporization). This, combined with the impact force of the CO2 pellets, blows away the unwanted surface contaminants, debris, stains, or coatings.

The dry ice process takes cleaning what would be considered a challenging and time-consuming job to an easy-to-handle project to complete.

Technique Matters

Using proper techniques for dry ice blasting is important for optimal results—the following consists of tips on how to use dry ice blasting for the best results and benefits.

- Keeping the angle of the nozzle consistent for the duration of the blasting session.

- Limit overlapping of the nozzle swath to maximize the use of blasting dry ice and minimize cleaning time.

- Typically keep the sweeps of your nozzle moving from top to bottom.

- Find an effective and consistent speed for sweeping the nozzle. Going too fast may cause a spotty result while going too slow will leave the target clean, but it can leave you spending unnecessary time and dry ice.

- The distance between the nozzle and the target should be between 2-6 inches.

- Avoid 45–90-degree bends or kinks in the blast hose and do not allow the hose to lie on hot dies or molds to extend the life of the blast hose and prevent electrical issues and shorts in the control cables.

Note that the most common mistake made while dry ice blasting is paying too little attention to the angle and direction you are blasting.

The Benefits of Dry Ice Blasting

Dry ice blasting can be used in an assortment of applications and has many benefits that make it a sensible choice for Restoration. Here are some of the main advantages of using this method.

- Non-Abrasive- Manual techniques use abrasive tools and chemicals that can cause damage to surfaces. Dry ice blasting effectively cleans surfaces without causing erosion and etching while efficiently removing char, soot, and smoke. It has better penetration, cleaning behind and between structural members without damage to surface integrity.

- Quick and Efficient- Traditional cleaning methods can take three to five times longer than cleaning with dry ice. Dry ice blasting eliminates the need for sandblasting, sanding, scraping, or wire brushing, and it is 100% effective. When a business or home is affected by fire, the dry ice blasting method restores structure quicker than ever before.

- Chemical-free Cleaning- During manual cleaning practices, technicians are exposed to chemicals and ultra-fine dust particles. Therefore, these methods are considered unsafe for those in the immediate area. Dry ice blasting is a chemical-free method, making it safe to use, non-combustible, leaves no residue, and safe for the ecosystem.

- Non-conductive- Dry ice blasting is non-conductive, ensuring the process is safe for sensitive electrical items such as switches, wiring, motors, and plumbing. Due to this, it allows you to clean all surfaces and hard-to-reach areas without worrying about electrical components. Most importantly, getting these hard-to-clean and hard-to-reach areas ensures that the residual effects of soot, smoke, and mildew will leave customers worry-free long after the job is complete.

- No Media Waste-Frequently the “clean-up” from current cleaning methods is worse than the cleaning itself. Dry ice solves that problem by eliminating secondary waste. Dry ice pellets do the job and simply disappear, eliminating the high disposal costs associated with other materials.

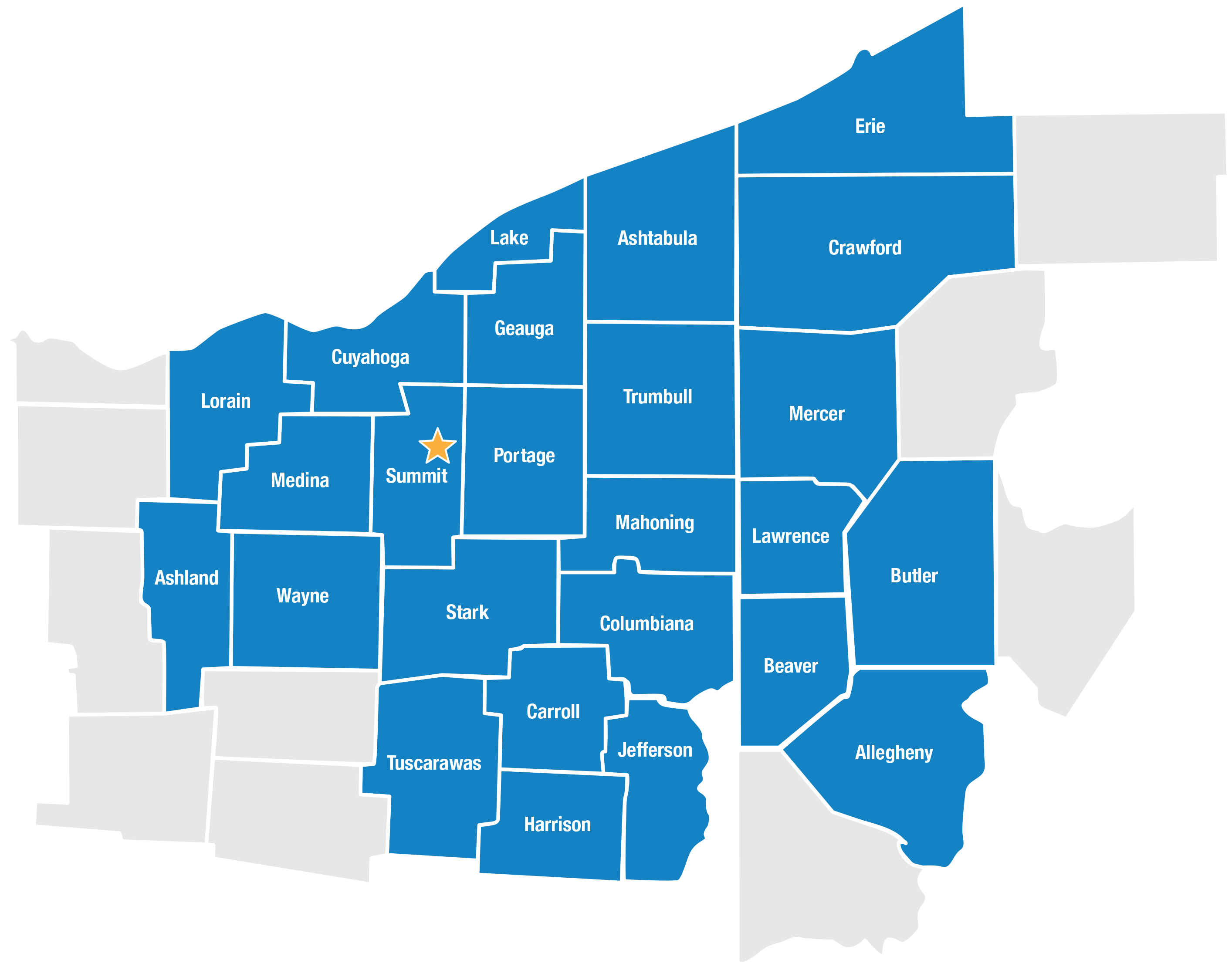

Trident Restoration specializes in dry ice blasting. We take pride in having the ability to take large and unique jobs and restoring the structural integrity of buildings with this method. Using this process allows us to help businesses open back up with as minimal disruption as possible and help homeowners restore their structures without the replacement costs and save and restore historical wood to its pre-damaged form. Contact us at 330-409-8000 if you have questions or feel your building could benefit from the use of dry ice. Trident Restoration is available 24/7 to help those impacted by disaster.